Safety Tread and Flooring Metal Bar Gratings

- Smooth or Non-slippery Serrated, Technical Reference Quality, Materials, Installation

Metal Bar Grating refers to a variety of bar grating processed from metallic bars and plates, including mild steel, galvanised steel, aluminum, stainless steel through either welding or locking, for industrial walkway, engineering projects, architectural and various applications.

Metal bar grating surface types:

The metal grating panels are made with a plain or serrated bars, and the serrated bar grating has improved grip and safety in numerous worker environments which assists in reducing valuable workforce downtime through possible injuries.

Benefits of Serrated Bar Grating:

Serrated grating has a Non-slip surface compared with flat or smooth metal bar grate, offering more safety suitable for stairtreads for slippery areas, or where safety is a consideration. Serrated bar grating usually has an additional depth compared with flat surface metal grating to ensure the proper loading rate.

Metal Bar Grating Types according to metal materials:

We supply a variety of metal bar gratings: stainless steel bar grating, aluminum bar grating, anodised aluminum grating, galvanized grating, mild steel grating.

Material Grade:

ASTM A36, A1011, A569, Q235, S275JR, SS304, SS400, Mild steel & Low carbon steel, etc.

Surface Treatment:

Black, self colour, hot dip galvanized, painted, spray coating

Grating Style:

Plain / Smooth, Serrated /teeth, I bar, serrated I bar.

Standards We Follow in Manufacturing Metal Gratings:

China: YB/T 4001.1-2007, USA: ANSI/NAAMM(MBG531-88),

UK: BS4592-1987, Australia: AS1657-1985,

Germany: DIN24537-1-2006, Japan:JIS.

According to loading capacities, Kingde offers Three Types of Gratings:

Light duty bar grating for walkways.

Loading UDL 300kg/m²

Applied to maintenance Platforms, Catwalks, Conveyor Walkways, Restricted to one-person traffic.

Medium duty walkways

Loading UDL 500kg/m²

General Production Platforms, Restricted to regular two-way pedestrian traffic.

Heavy duty

For walkways Loading UDL 750kg/m²

General Production Platforms, High Density Pedestrian Traffic.

METAL BAR GRATING QUALITY REFERENCES

The metal gratings we produce can meet following quality standards, submitting procedure, packing, materials requirements, products requirements, finishes, and installation requirements.

American Institute of Steel Construction (AISC): Specification for Structural Steel for Buildings.

American National Standards Institute (ANSI): ANSI B18.5 - Round Head Bolts (Inch Series). ANSI B18.6.1 - Wood Screws (Inch Series).

American Society of Civil Engineers (ASCE): ASCE / SEI 7 - Minimum Design Loads for Buildings and Other Structures.

American Society for Testing and Materials (ASTM):

- ASTM A 27 / A 27M - Specification for Steel Castings, Carbon, for General Application.

- ASTM A 47 / A 47M - Specification for Ferritic Malleable Iron Castings.

- ASTM A 48 / A 48M - Specification for Gray Iron Castings.

- ASTM A 36 / A 36M - Specification for Carbon Structural Steel.

- ASTM A 53 / A 53M - Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless.

- ASTM A 123 / A 123M - Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- ASTM A 134 - Specification for Pipe, Steel, Electric-Fusion (Arc)-Welded (Sizes NPS 16 and Over).

- ASTM A 153 / A 153M - Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware.

- ASTM A 167 - Specification for Stainless and Heat-Resisting Chromium-Nickel Steel Plate, Sheet, and Strip.

- ASTM A 176 - Specification for Stainless and Heat-Resisting Chromium Steel Plate, Sheet, and Strip.

- ASTM A 276 - Specification for Stainless Steel Bars and Shapes.

- ASTM A 307 - Specification for Carbon Steel Bolts and Studs, 60,000 PSI Tensile Strength.

- ASTM A 500 / A 500M - Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Round and Shapes.

- ASTM A 501 - Specification for Hot-Formed Welded and Seamless Carbon Steel Structural Tubing.

- ASTM A 568 / A 568M - Specification for Steel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements for.

- ASTM A 653 / A 653M - Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process.

- ASTM A 780 - Practice for Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized Coatings.

- ASTM C 1107 / C 1107 - Specification for Packaged Dry, Hydraulic-Cement Grout (Nonshrink).

- ASTM E 330 - Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference.

- ASTM E 935 - Test Methods for Performance of Permanent Metal Railing Systems and Rails for Buildings.

- ASTM E 936 - Practice for Roof System Assemblies Employing Steel Deck, Preformed Roof Insulation, and Bituminous Built-Up Roofing.

American Welding Society (AWS):

AWS D1.1 / D1.1M - Structural Welding Code - Steel.

Americans with Disabilities Act Accessibility Guidelines (ADAAG): Accessibility Guidelines for Buildings and Facilities.

International Code Council: International Building Code (IBC), 2009.

National Association of Architectural Metal Manufacturers (NAAMM):

- Metal Finishes Manual for Architectural and Metal Products.

- MBG 531 - Metal Bar Grating Manual.

- MBG 532 - Heavy Duty Metal Bar Grating Manual.

- MBG 533 - Welding Specification for Fabrication of Steel, Aluminum and Stainless Steel Bar Grating.

SSPC: The Society for Protective Coatings (formerly Structural Steel Painting Council):

- SSPC Painting Manual.

- SSPC PA 1 - Specification Procedure for Shop, Field and Maintenance Painting of Steel.

- Paint 20 - Specification of Zinc-Rich Coating Type 1 - Inorganic and Type II - Organic.

- SSPC SP 2 - Requirements for Hand Tool Cleaning of Steel Surfaces.

- SSPC SP 3 - Requirements for Power Tool Cleaning of Steel Surfaces.

- SSPC SP 6 - Standard for Commercial Blast Cleaning of Steel Surfaces.

- SSPC SP 7 - Standard for Brush-Off Blast Cleaning of Steel Surfaces.

- VIS 3 - Guide and Reference Photographs for Steel Surfaces Prepared by Power and Hand-Tool Cleaning.

SUBMITTALS

Submittal Procedures:

- Product Data: Manufacturer's specifications, and installation instructions for pre-manufactured products.

- Drawings:

a. Drawings for fabrication and erection of miscellaneous metal fabrications.

b. Where materials or fabrications are required to comply with requirements for design loadings, include structural computations, materials properties and other information for structural analysis. Prepare under the seal of a professional structural engineer for products requiring structural engineering to meet the Performance Requirements.

c. Include profiles, sizes, connection attachments, reinforcing, anchorage, size and type of fasteners and accessories, erection drawings, elevations, welded connections using standard AWS welding symbols with net weld lengths.

- Samples:

a. Submit representative samples of materials and finished products as requested.

QUALITY ASSURANCE

Performance Requirements:

- Provide the capacity to withstand the required loading requirements:

a. Design, fabricate and install to resist combined positive and negative windloading in accordance with IBC 2009, Section 1609 with a Vmph of 170, qs of 74.0 psf, exposure C and importance factor 1.0, as applicable per ASCE 7. - Provide assemblies which, when installed, comply with the following minimum requirements for structural performance, unless otherwise indicated.

a. Treads and Platforms of Steel Stairs: Capable of withstanding a uniform load of 100 pounds per square foot, or a concentrated load of 300 pounds so locates as to produce maximum stress conditions.

DELIVERY, STORAGE AND HANDLING

- Section 01600 - Product Requirements: Transport, handle, store and protect the products.

- Protect materials from corrosion, deformation and other damage during delivery, storage and handling.

- Deliver product to the Project Site in the fabricator's original, unopened packages, containers or bundles.

- Store and protect the materials with a weatherproof covering; ventilate to avoid condensation.

PRODUCTS MATERIALS

- Use only materials which are smooth and free of surface blemishes including pitting, seam marks, roller marks, rolled trade names and roughness for fabrication of miscellaneous metal work which will be exposed to view.

- Steel Plates, Angles, and Other Structural Shapes: ASTM A 36 / A 36M.

- Steel Pipe: ASTM A 53 / A 53M. Type and grade (if applicable), as selected by the fabricator and as required for the design loading. Black finish, unless galvanizing is indicated. Standard weight (Schedule 40), unless otherwise indicated.

- Galvanized Steel Pipe and Tube: ASTM A 53 / A 53M.

- Steel Tubing: Cold-formed, ASTM A 500 / A 500M or hot-rolled, ASTM A 501.

- Sheet Steel, Galvanized: ASTM A 123 / A 123M.

- Sheet and Strip Steel, Hot-Rolled: ASTM A 568 / A 568M.

- Structural Steel Sheet: Hot-rolled, ASTM A 134 or cold-rolled ASTM E 936, Class 1; of grade required for the design loading.

- Galvanized Structural Steel Sheet: ASTM A 653 / A 653M, of grade required for the design loading. Coating designation as indicated, or if not indicated, G90.

- Stainless Steel: AISI Type 304 for fumed and welded products. ASTM A 276 for base shapes and forging; ASTM A 167 or A 176 as best suited for plates, sheets and strip. Satin finish typical.

- Gray Iron Castings: ASTM A 48, Class 30.

- Malleable Iron Castings: ASTM A 47, grade as selected by the fabricator.

- Steel Bar Grating: ASTM A 36 / A 36M or NAAMM MBG 531.

- Brackets, Flanges and Anchors: Cast or formed metal of the same type material and finish as the supported fabrications.

- Concrete Inserts. Threaded or wedge type; galvanized ferrous castings, either malleable iron, ASTM A 47, or cast steel, ASTM A 27. Provide bolts, washers and shims, as required, hot-dip galvanized, ASTM A 153.

- Non-Shrink, Non-Metallic Grout: Premixed, factory-packaged, non-staining, non-corrosive, non-gaseous grout complying with ASTM C 1107 (formerly CE CRD-C621). POR-ROK Anchoring Cement by Minwax Co. division of Eastman Kodak Co., or approved equal. Comply with the manufacturer's printed instructions.

- Welding Materials: AWS D1.1 / D1.1M. Type required for the materials being welded.

- Anchors:

- Threaded Type, Concrete Inserts: Galvanized malleable iron or cast steel capable of receiving 3/4" diameter machine bolts.

- Slotted Type, Concrete Inserts: Welded box type, fabricated with a minimum 1/8" thick galvanized pressed steel plate with slots to receive 3/4" diameter square head bolts, and knockout cover.

- Expansion Shield, Masonry Anchorage: FS FF-2-325.

- Toggle Bolts: FS FF-B-588, type, class and style as required.

- Fasteners:

- Provide zinc-coated fasteners for exterior use or where built into exterior walls, Select fasteners for the type, grade and class required.

- Bolts, Nuts and Washers at Interior Locations: ASTM A 307, Grade A, regular hexagon head.

- Bolts, Nuts and Washers at Exterior Locations: ASTM A 307, galvanized per ASTM A 153.

- Bolts, Round Head: ANSI B18.5.

- Lag Bolts: Square head type, FS FF-B-561.

- Plain Washers: Round, carbon steel, FS FF-W-92.

- Lock Washers: Helical spring type, carbon steel, FS FF-W-84.

- Masonry Anchorage Devices: Expansion shields, FS FF-S-325.

- Toggle Bolts: Tumble-wing type, FS FF-B-588, type, class and style as required.

- Machine Screws: Cadmium plated steel, FS FF-S-92.

- Wood Screws: Flat head carbon steel, FS FF-S-111.

- Primers:

- Primer for Field Painting: Provide one of the following:

- No. 99 Red Primer by Tnemec Co.

- Ceco No. 15 Primox by Chessman-Elliot Company.

- No. 7-C-19 by Rowe Products, Inc.

- Touch-Up Primer for Galvanized Surfaces: High zinc dust content paint for re-galvanizing welds in galvanized steel, complying with SSPC-Paint-20 and ASTM A 780.

- Section 01600 - Product Requirements: Product options and substitutions:

Substitutions: Permitted. - Concrete Fill:

- Concrete Materials and Properties: Comply with the requirements of Division 3 Sections for normal weight, ready-mix concrete with minimum 28-day compressive strength of 4,000 psi, 440 pounds cement per cubic yard, minimum, and a W/C ration of 0.65, maximum, unless higher strength is indicated.

- Non-Slip Aggregate Finish: Factory-graded, packaged material containing fused aluminum oxide grits or crushed emery as abrasive aggregate; rust-proof and non-glazing; unaffected by moisture and cleaning materials.

METAL BAR GRATINGS

- Provide close mesh bar gratings using bars of the type, material, sizes, spacing and construction indicated, or if not indicated, to support the truck loadings indicated. Comply with the "Standard Specifications for Metal Bar Grating and Metal Bar Grating Treads" portion of the NAAMM, "Metal Bar Grating Manual".

- Material: Steel.

- Type Grating: Welded.

- Bearing Bars: Size and shape as required by the anticipated loading.

- Cross Bars: Rectangular. Provide true alignment and equal spacing of the cross bars by notching the bearing bars prior to welding. Do not notch the bearing bars at supports to maintain elevation.

- Traffic Surface: Plain.

- Edge Band openings in the grating which interrupt four or more bearing bars with bars of the same size and material as the bearing bars.

- Steel Finish: Hot-dip galvanized with a coating of not less than 1.5 oz. per square foot of coated surface.

METAL STAIR NOSINGS

- Material: Cast aluminum with hatched aluminum abrasive surface, 1/4" nosing lip x 3" minimum depth, embedded; one piece the full width of stair treads and landings.

- Manufacturers:

- DSA3 by American Safety Technologies.

- Style 3511 by American Safety Tread Co.

- Type 231 by Wooster Products Inc.

- Section 01600 - Product Requirements: Product options and substitutions: Substitutions: Permitted.

FABRICATION

- Fabricate steel items according to the approved Shop Drawings and to the applicable portions of AISC Specifications.

- Pre-assemble products in the shop to the greatest extent possible. Disassemble units only as necessary for shipping and handling limitations. Clearly mark units for re-assemble and installation.

- For fabrications exposed to view, use materials which are smooth and free of surface blemishes including pitting, seam marks, roller marks, roller trade names and roughness. Remove blemishes by grinding or by welding and grinding prior to cleaning, treating and the application of surface finishes, including zinc coating.

- Workmanship: Use materials of the size and thickness indicated or, if not indicated, as required to produce the strength and durability in the finished products for the intended use. Work to the dimensions indicated or accepted on the Shop Drawings, using proven details of fabrication and support. Use the type of materials indicated or specified.

- Form exposed work true to line and level with accurate angles and surfaces and straight sharp edges. Fabricate items with joints tightly fitted and secured. Make exposed joints butt tight, flush and hairline. Ease exposed edges to a radius of approximately 1/32", unless otherwise indicated. Form bent-metal corners to the smallest radius possible, without causing grain separation or otherwise impairing the work.

- Conceal welds where possible. Weld corners and seams continuously, complying with AWS and the Building Code. At exposed connections, grind the exposed welds smooth and flush to match and blend with the adjoining surfaces.

- Form exposed connections with hairline joints, flush and smooth using concealed fasteners wherever possible. Use exposed fasteners of the type indicated or, if not indicated, Phillips flat-head (countersunk) screws, or bolts.

- Exposed Mechanical Fastenings: Flush countersunk screws and bolts, unobtrusively located, except where specifically noted otherwise; consistent with the design.

- Provide anchorage of the type indicated, coordinated with the supporting structure. Fabricate and space anchoring devices to provide adequate support for the intended use. Fabricate anchorage and related components of the same material and finish as the metal fabrication, unless indicated otherwise.

- Cut, reinforce, drill and tap miscellaneous metal work, as indicated, to receive the finish hardware and similar items.

- Fabricate joints which will be exposed to weather in a manner to exclude water, or provide weep holes where water may accumulate.

- Galvanizing: For items indicated to be galvanized, apply zinc-coating by the hot-dip process in compliance with the following requirements:

- ASTM A 153 / A 153M for galvanizing iron and steel hardware.

- ASTM A 123 / A 123M for galvanizing both fabricated and un-fabricated iron and steel products made of un-coated rolled, pressed, and forged shapes, plates, bars, and strip 0.0299" thick and heavier.

- ASTM A 123 / A 123M for galvanizing assembled steel products.

FINISHES, GENERAL

- Comply with NAAMM, Metal Finishes Manual for Architectural and Metal Products, for recommendations relative to the application and designation of finishes.

- Finish metal fabrications after assembly.

PAINTING AND PROTECTIVE COATING

- Conform to SSPC-PA 1, including preparation for painting.

- Apply shop primer to un-coated surfaces of metal fabrications, except those with a galvanized finish or to be embedded in concrete, masonry, or sprayed-on fireproofing, unless otherwise indicated. Comply with the requirements of SSPC-PA 1, APaint Application Standards, Guides and Specifications No. 1", for shop painting.

- Preparation for Shop Priming: Prepare un-coated ferrous metal surfaces to comply with the minimum requirements indicated below for SSPC surface preparation specifications and the environmental exposure conditions of the installed metal fabrications:

- Interiors (SSPC Zone 1A): SSPC-VIS 3.

- Exteriors (SSPC Zone 1B): SSPC-SP 6.

- Shop primer for Ferrous Metal: Fast-curing, lead-free, abrasion-resistant, rust-inhibitive primer selected for compatibility with the substrates and with the types of alkyd-type paint systems indicated, and for compatibility to provide a sound foundation for field-applied topcoats, despite prolonged exposure; complying with the performance requirements of FS TT-P-86, Types I, II and III.

- Hot-Dip galvanizing and zinc coatings applied on products fabricated from rolled, pressed, and forged steel shapes, plates, bars and strips shall comply with ASTM A 123 / A 123M. Galvanized surfaces, for which a shop coat of paint is specified, shall be chemically treated to provide a bond for the paint. Except for bolts and nuts, all galvanizing shall be done after fabrication.

- Clean surfaces of rust, scale, grease and foreign matter in accordance with SSPC-SP 1 Solvent Cleaning, prior to finishing. Prepare surfaces for painting in accordance with SSPC-SP 2, SSPC-VIS 3 or SSPC-SP 7.

- Do not prime surfaces that will be in direct contact with concrete, or where field welding is required.

- Prime paint items scheduled, with one coat.

INSTALLATION OF Metal Bar Gratings:

- Comply with the recommendations of NAAMM, "Metal Bar Gratings Manual", for the installation of gratings, including installation clearances and standard anchoring details.

- Secure removable units to supporting members with the type and size clips and fasteners indicated, of if not indicated, as recommended by the grating manufacturer for the type of installation conditions shown.

- Secure non-removable units to supporting members by welding where both materials are the same, otherwise fasten by bolting, as indicated.

Applications Illustrations:

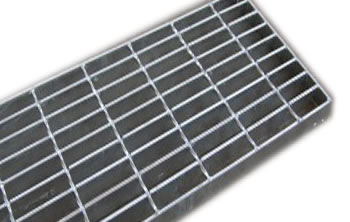

Grating Treads:

Prefabricated Steel Bar Tread

Metal Bar Walkway Decking:

Trench Covers:

Heavy Duty Safety Flooring Panels:

Steel Grating, Serrated,30-102 and 30-51

Popular Metal Grating Products:

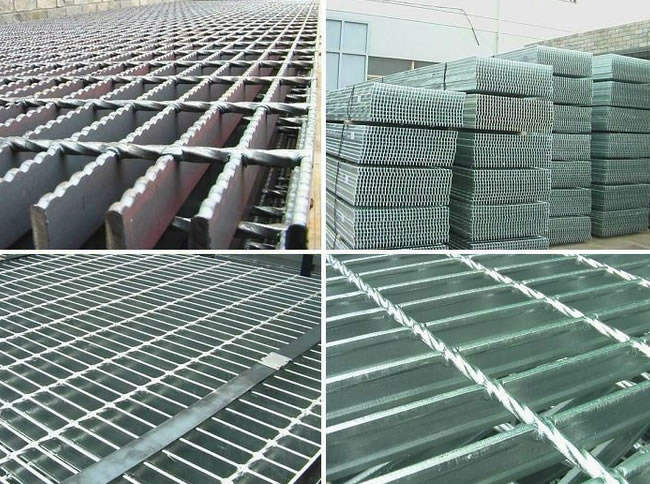

Hot dipped galvanized cross bar steel grating

Bearing bar thickness (mm):3

Bearing bar width (mm):40

Cross bar diameter (mm):6

Bearing bar pitch/distance (mm):40

Cross bar pitch/distance (mm):100

Surface treatment: galvanized

Hot dipped galvanized plain steel bar grating

Bar Grating

- Hot Dip Galvanised Floor Grating

- Steel Grating Panels

- Anodised Alumium Grating

- Platform Steel Grating

- Standard Grating Panels

- Swage Locked Bar Grating

- Drain Covers Steel Grating

- Compound Steel Bar Gratings

- Pressure Locked Steel Bar Grating

- Safety Non-Slippery Metal Gratings

- Fabricated Steel Grating Decking

- Stainless Steel Bar Grates

- Aluminum Stair Tread

- Aluminum Bar Grating