"about us"

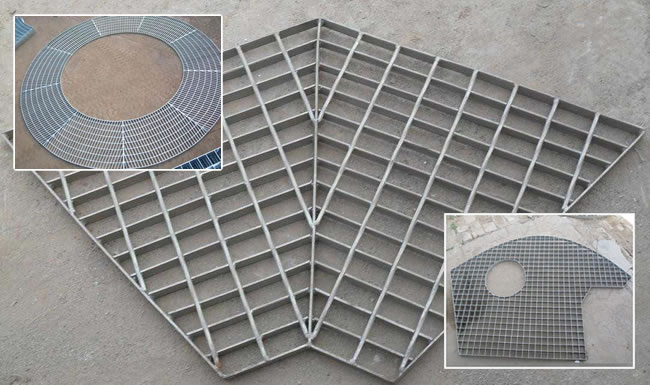

Kingde offers a wide range of standard grating panels cut to sizes, and tailored to drawing panels to meet specific requirements. Gratings can be smooth grating and serrated grating according to bar types and the serrated grating offers more non slip safety. Bar gratings according to processing and structures, can be divided into Welded Bar Grating, Pressure Locked and Swage Locked Metal Gratings.

Material Grade:

ASTM A36, A1011, A569, Q235, S275JR, SS304, SS400, Mild steel & Low carbon steel, etc.

Surface Treatment:

Black, self colour, hot dip galvanized, painted, spray coating

Grating Style:

Plain / Smooth, Serrated /teeth, I bar, serrated I bar.

Standards We Follow in Manufacturing Metal Gratings:

China: YB/T 4001.1-2007, USA: ANSI/NAAMM(MBG531-88),

UK: BS4592-1987, Australia: AS1657-1985,

Germany: DIN24537-1-2006, Japan:JIS. Learn more.

Featured Products:

Anodised Alumium Grating, beautiful grating panels for architecture and access covers.

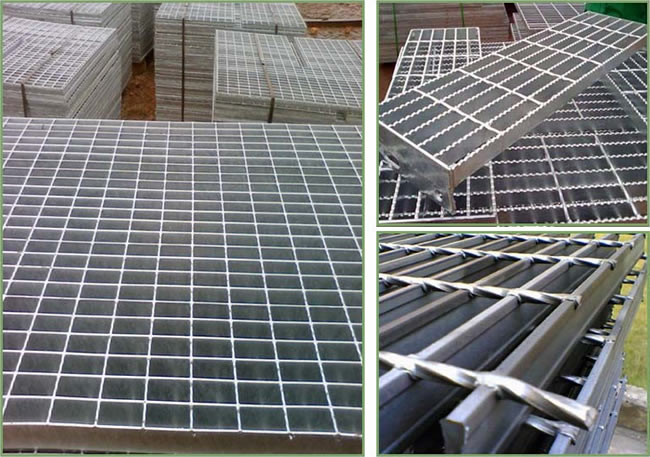

Welded Steel Bar Decking Grating is the most popular of all grating types due to its strength, cost-efficient production and ease of installation. Universally used in most general industrial plants as well as commercial buildings, it has wide applications as walkways, platforms, safety barriers, drainage covers and ventilation grates.

It is also ideal for use as mezzanine decking since it supports the same loads as comparable solid flooring. More than that, its cost saving openness maximizes the circulation of air, light, heat, water and sound, while promoting cleanliness. And, where insurance codes permit, additional sprinklers can often be eliminated.

Standard panels are available in widths of 2', 3' or 4'.

Swage Locked I-Bar Grating Panels:

I-bar swage-locked is lighter weight and less costly than a rectangular bar grating with the same bar thickness, though I-bars reduce the open spaces of the grating because of the flange width. I-bar swage-locked maintains load ratings, it provides the strength equal to a rectangular bar of the same depth, but at far less weight.

Composite I bar type Welded Corten Steel Grating:

High strength, light structure: solid grid pressure welding structure has advantages of high load, light structure, easy installation, etc.

Fine appearance, durable in use: hot zinc dipping surface treatment makes it own fairly good corrosion resistance, bright and beautiful surface.

Good ventilation, lighting, thermal, anti-explosion, and anti-skid performance.Learn more about Bar Gratings by Terminology Terms.

Perforated Chequered Plates for Prefabricated Grating Stair Treads surface anti-skidding treatment:

Treads surface anti-skidding treatment:

Kingde offers components checkered plates for slippery proof flooring uses. The perforated metal plates are checkered with diamond patterns, they are applied for grating floors for two specific uses. One is used as nosing of bar grating panels, the other is used as top of grating flooring with improved anti-slippery property to ensure the step safeties.

Mainly aluminum five-bar chequered plates, dur bar or three bar plates. We also supply galvanized steel multi-bar diamond plates for customers.

Read More About Us

We are grating manufacturer and exporter,we offer bar grating made of a wide range of meterials, through several processing types in timely delivery: Pressure Locked Steel Bar Grating,Standard Grating Panel,Stainless bar steel grating, Aluminum Bar Grating, Galvanized Grating, etc. Materials widely used are mild steel, stainless steel and aluminum, with 3mm * 5mm thickness, in flat form and serrated flat. U.S.A NASI/NAAMM standards.

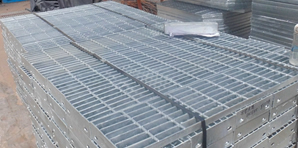

We are grating manufacturer and exporter,we offer bar grating made of a wide range of meterials, through several processing types in timely delivery: Pressure Locked Steel Bar Grating,Standard Grating Panel,Stainless bar steel grating, Aluminum Bar Grating, Galvanized Grating, etc. Materials widely used are mild steel, stainless steel and aluminum, with 3mm * 5mm thickness, in flat form and serrated flat. U.S.A NASI/NAAMM standards. We offer standard steel bar grating and specific sizes. Processes include: confirming steel grating size, flat longitudinal trim, automatic welding, steel grille frame lock, hot-dip galvanized surface, anti-corrosion treatment. Large span, high strength, many specifications available. Hot-dip galvanized, good antirust performance, maintenance free and replacement free. Galvanized steel grating maximum length of seven meters can be achieved, no welding slag, bright, smooth and beautiful.

We offer standard steel bar grating and specific sizes. Processes include: confirming steel grating size, flat longitudinal trim, automatic welding, steel grille frame lock, hot-dip galvanized surface, anti-corrosion treatment. Large span, high strength, many specifications available. Hot-dip galvanized, good antirust performance, maintenance free and replacement free. Galvanized steel grating maximum length of seven meters can be achieved, no welding slag, bright, smooth and beautiful.  Our bar grating mesh panels are widely used in flooring, landing and safety treads: Platform Steel Grating,Drain covers steel grating, Bar Grating Stair Treads, Aluminum Stair Tread, Steel Bar flooring, Fabricated Mild Steel Deck Grating, Compound Steel Bar Gratings. Welcome to our factory to inquire.

Our bar grating mesh panels are widely used in flooring, landing and safety treads: Platform Steel Grating,Drain covers steel grating, Bar Grating Stair Treads, Aluminum Stair Tread, Steel Bar flooring, Fabricated Mild Steel Deck Grating, Compound Steel Bar Gratings. Welcome to our factory to inquire.